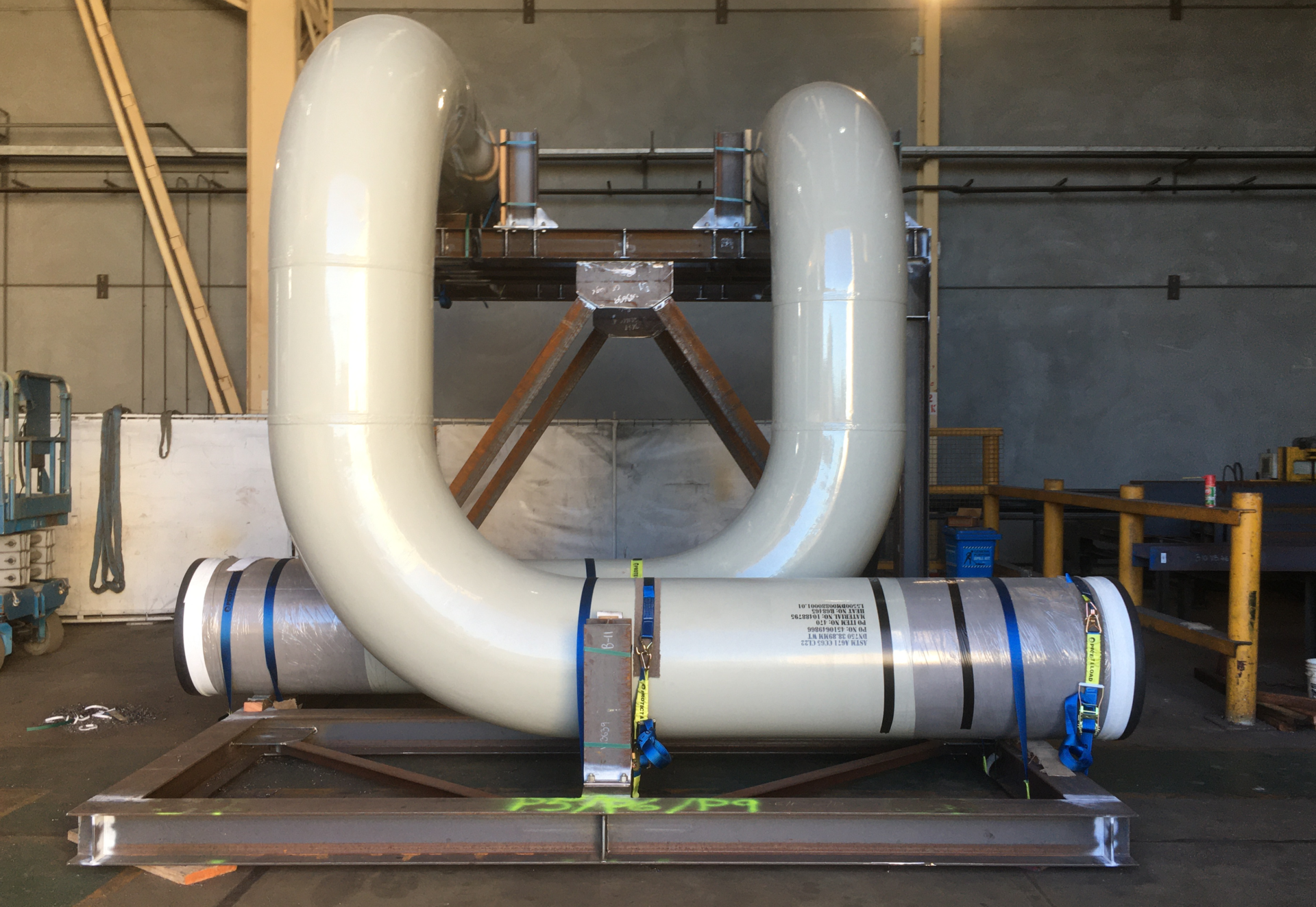

The complex LTCS and duplex bore spools fabrication included:

– 750 NB Piping heavy wall piping

– 100+ welded joints completed with minimal weld repairs

– TIG, FCAW, SAW and TIP-TIG welding techniques utilised

– Humidur coating applied

– Hot work insulation

Fabrication of the large pipe bridges and structures included:

– > 60 tonne Plus trestles and pipe bridges

– L0 testing and Z25 testing applied to all material

– 100+ Pipe supports

– Surveyed structure for easy install on site

The spools fabrication was complex, with weld procedure specifications required for duplex/carbon overlay welding and an acute focus on quality was maintained throughout to achieve the desired result.

The fabrication was completed over of 20,000+ man hours with Zero LTI’s.

CASE STUDIES

Cloudbreak Iron Ore Mine Expansion

AGC and Kiewit partnered in a JV for the contract which included the addition of; a…

Woodside Energy Limited – Fabrication Services Contract

AGC was awarded the contract for the provision of fabrication services in support of the maintenance…

Woodside-operated North West Shelf (NWS) Project – Karratha Gas Plant (KGP) Multidiscipline Services Agreement (MDSA)

The scope of work focused on mechanical works, structural steel, site installation and welding, inspection, cladding…