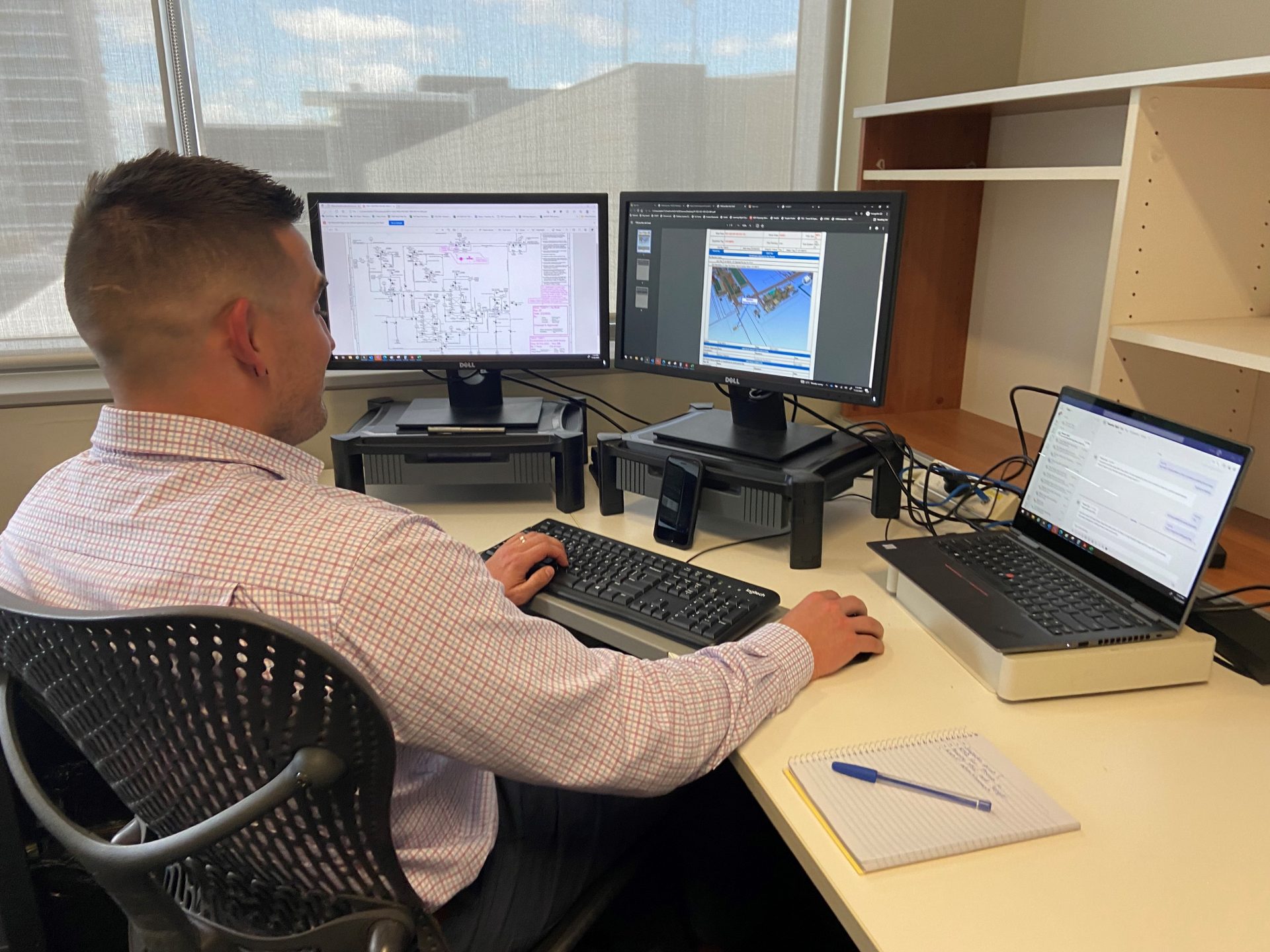

The Project

The TAR Planning Team of over 90 staff comprised of specialist disciplines working in an integrated approach with the client. The team focused on maximising efficiency, cost savings and identifying risk mitigations in the early planning stages of each TAR event, including:

- Work packing

- Event management

- Execution leads and support

- Planning and scheduling

- Production support

- Materials specialists

- Resources planning

- QA/QC & completions

- Shutdown engineers

- Structural Mechanical Engineers

- Procurement

Continuous Improvement

Lessons Learned workshops for the TAR 501 and 502 highlighted:

- Team consistency across both projects provided experience efficiency

- Dashboard Development – increased performance clarity on performance targets

- MODS work pack standardisation for consistency

- Co-location of Chevron and AusGroup planning teams

- Rigorous change management process for tracking and managing

CASE STUDIES

Woodside-operated North West Shelf (NWS) Project – Karratha Gas Plant (KGP) Multidiscipline Services Agreement (MDSA)

The scope of work focused on mechanical works, structural steel, site installation and welding, inspection, cladding…

Rio Tinto – Rope Access Maintenance Crews Pilbara Mine Sites

AusGroup was contracted by Rio Tinto to provide a pool of Rope Access technicians for maintenance…

Dampier Salt Stacker Fabrication and Install (CV007)

As part of contract CV007 AusGroup fabricated approx. 77t of steelwork fabrication for a replacement stacker…